Rivet gun for machinery-related work is not unfamiliar, but the working principle of the rivet gun is not very well understood; today, BOFENG‘s editor will take you to understand the working principle of the rivet gun, a complete understanding of the tool will be used in work more smoothly, the service life of the tool longer.

Usually, riveting is inserted by the side of the plate rivet and must be top iron pad top, and then riveting. Still, with rivet gun riveting, only a single side of the operation can be completed.

Riveting with a gun is often used for riveting on the bottom side where the hand or top iron cannot reach.

The principle of riveting with a pull rivet:

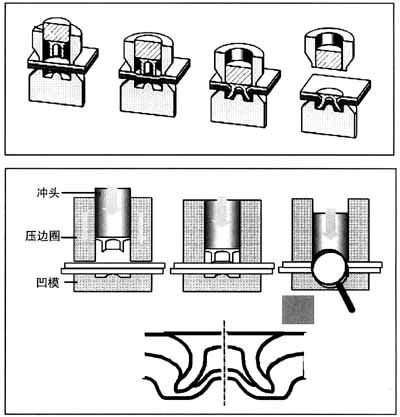

The pull rivet is a hollow rivet with a central stalk, the end of the stem is round collar-shaped, and the center has a scale; the operation of the first drill rivet holes, insert the pull of the rivet, the use of manual or pneumatic.

The rivet gun’s chuck sets the riveting nail stems and apply tension to the rivet nail stems bite; the branches of the head under pressure will force the material of the softer riveting nail head outward expansion into the flange shape so that the fabric is closely combined, and then once again add tension until the nail stems are pulled off, you can rivet the plate.

Advantages of riveting with a rivet gun:

unidirectional operation with no noise; no damage to the workpiece; light, easy and hygienic work; labor-saving, time-saving, and accurate; high strength

Rivet gun pulls rivet specifications and types of rivets.

1, pull rivets, according to the different materials, can be divided into aluminum alloy remove clips and stainless steel pull hooks, two kinds of pins.

2, according to the different shapes of the rivet head, pull rivets can be divided into round head-shaped pull rivets and dish head type pull clips.

Rivet gun riveting nail selection

Before using the rivet gun to rivet the workpiece, choosing the proper pulling rivet is essential. The selection of buckles usually follows the following principles.

1, according to the workpiece material selection of the same material pull rivets.

2, the general material used to join the aluminum alloy round head Latin.

3, the surface of the workpiece requires a smooth choice of dish head rivets.

4, in places containing corrosive substances such as acid, choose stainless steel rivets.

5, the diameter of the rivet, length, and plate thickness to choose the appropriate rivet pulling.

6、The diameter of the material hole is larger than the diameter of the pull rivet of about 0.1mm.

The structure of the rivet gun:

Manual rivet guns can be divided into the expected and decisive types. The size of the rivet gun depends on its length. The rivet gun is equipped with several nozzles, marked with different calibers, which can be loaded and unloaded for alternate use as required.

The rivet gun has a steel claw that grips the nail stems and compresses the nail head to make a tight fit.

At present, pneumatic rivet guns are also more common; using a pneumatic rivet gun can save a lot of time and workforce. The principle of action is that the compressed air from the connecting tube through the valve to the piston so that the piston in the body of the gun to do reciprocal movement so that the rivet is formed; the general use of air pressure of about 0.1-0.7m3 / min, with a number of the gun nozzle, the above has a different aperture, can be loaded and unloaded according to the actual needs of alternate use.